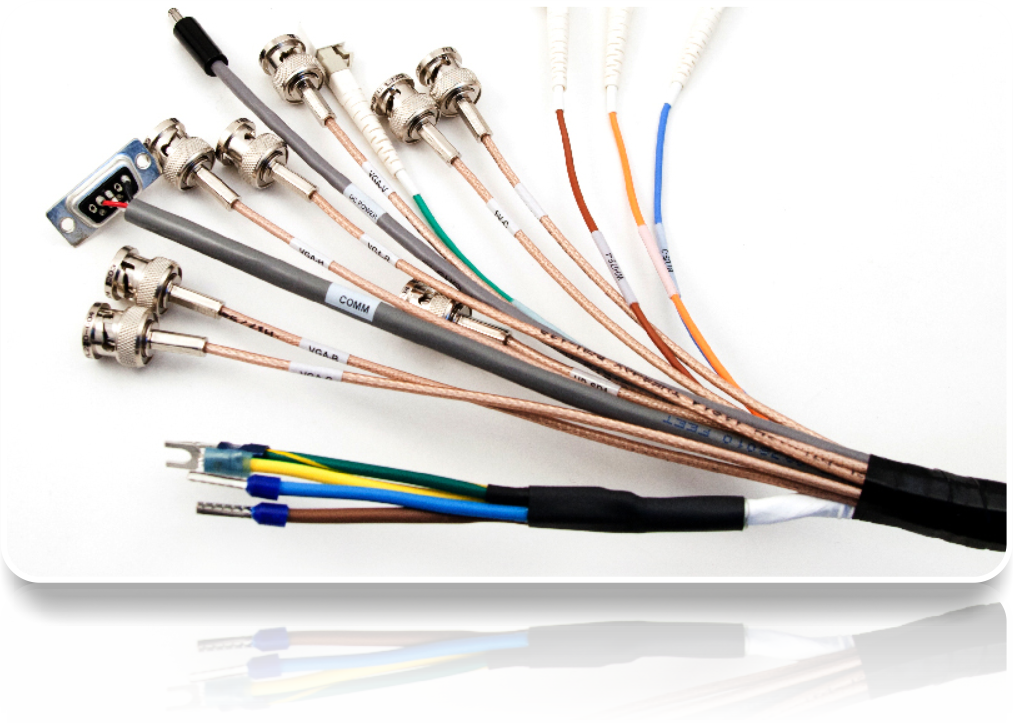

Harness & EWS division is be responsible to prepare wire requirement with experience will support our team to build games machines, vending machines, etc.

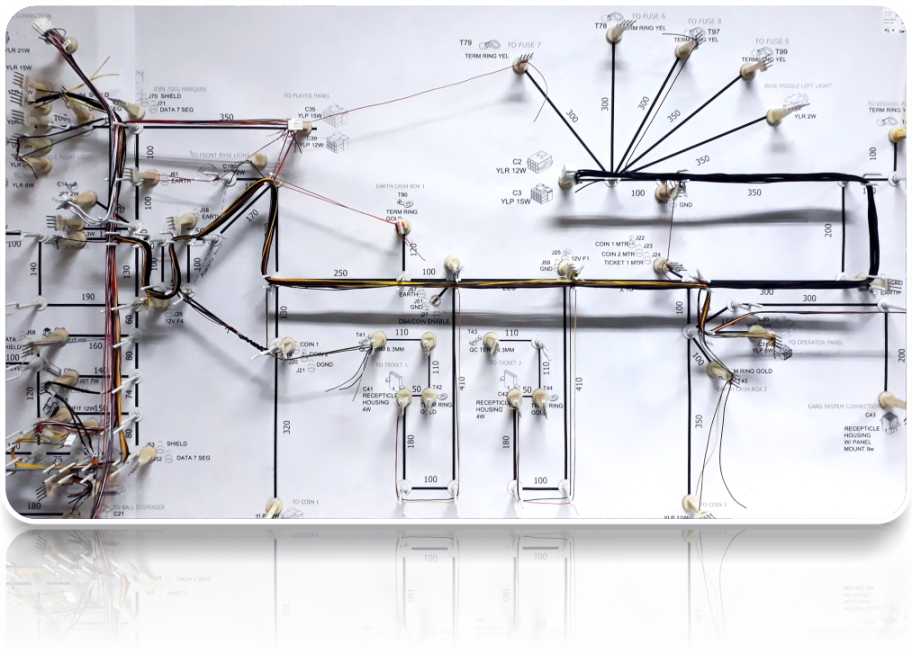

Cable harnesses are usually designed according to geometric and electrical requirements. A diagram is then provided (either on paper or on a monitor) for the assembly preparation and assembly.

The wires are first cut to the desired length, usually using a special wire-cutting machine. The wires may also be printed on by a special machine during the cutting process or on a separate machine. After this, the ends of the wires are stripped to expose the metal (or core) of the wires, which are fitted with any required terminals or connector housings. The cables are assembled and clamped together on a special workbench, or onto a pin board (assembly board), according to the design specification, to form the cable harness. After fitting any protective sleeves, conduit, or extruded yarn, the harness is either fitted directly in the vehicle or shipped.

We have a fully equipped wood shop that can handle working with various sizes and types of wood and composite materials. Our woodworking machines are capable of working with materials such as Plywood, MDF, Acrylic, Polycarbonate, ABS and other Plastics.

Our process layout design and production system, supported by our own machines and skilled personnel, guarantees optimal output. Our Wood Shop Equipment includes:

With skillful and professional employees, we use only the best tools and apply superior techniques during the fabrication process, ensuring our products meet the highest quality standards.

CNC Laser Cutting machines, known for their speed and accuracy, are truly on the "cutting edge" of technology. These machines cut fine and complex shapes from metal plates up to a maximum thickness of 16 mm. The integrated CADMAN software takes care of the whole system, starting from the design process and programming through to the cutting process.

CNC bending machines are able to bend sheet metal up to 6 mm in thickness and 3000 mm in length. With computerized Brake Bending control, we guarantee consistent quality. It is fast to set up, efficient and cost effective.

CNC Punching machines are suitable for small and medium jobs and are very cost effective for low volumes of work. With a rotary head and a variety of punches, they have the ability to follow, cut or punch any contour or shape and are flexible enough to perform special forming functions and taping.

Our equipment is fully capable of performing all welding processes to various materials from mild steel, to aluminum, to stainless steel. Supported by certified and experienced welders, we are able to produce the highest quality products.

Printing division had good skill to make best result for our products. State-of-the-art technology and highly skilled staff ensure strong and competitive solutions for print and screening your needed.

We offer plastic Vacuum Forming service for specialist one off jobs (prototypes) as well as full batch production runs. Our vacuum forming service produce plastic parts for various industries, such as signage, interior, medical, electronics, entertainment and automotive.

Vacuum forming is a process where plastic sheet is heated to its transition temperature and placed in contact with a mold. The plastic sheet is formed into a new shape with pressure from the vacuum. Vacuum forming is a great solution when the customer needs too many units to fabricate by hand and too few units for injection molding.

We specialise in bespoke custom plastic vacuum forming projects from large piggy banks, giant boots to giant bottle displays. Alternatively our vacuum forming machines are kept busy with large production runs of bespoke gear trays, sunbed panels and lighting fixtures. Our CNC machinery and trimming service ensures rapid turn-around at all times.

Our in-house design teams are available to help with material selection, CAD / CAM designs, offer 3D visuals and produce initial prototypes to bring your projects to life. Our skilled fabricators can produce quality in-house tooling or alternatively bring in specialist aluminum tooling for vacuum fumed parts that requires maximum precision. Contact us now to discuss your custom plastic vacuum forming requirements.

Our assembly division has experience to assembling product with high speed and accuracy assemble. Capable to using any assembly tools and read the drawing assembly properly.

Our skillful and professional employees use only the best tools and apply superior techniques and methode during the assemble process, ensuring our products meet the highest quality standards.

PT. Matahari Leisure

Millenium Industrial Estate Blok C 1,

Tigaraksa, Peusar, Panongan

Tangerang - Banten 15720

(+62)21 5994940 / 42